Organization of

production processes

01

Product life cycle

management

02

Equipment maintenance

planning

03

Resource and cost

optimization

04

Implementation of an ERP system contributes to sustainable business growth through effective resource management

Key ERP functions for the metalworking industry

Production cycle

management

management

Equipment utilization

optimization

optimization

Financial planning

and analysis

and analysis

Shift and work

schedule management

schedule management

Logistics process

control

control

Raw materials

accounting

accounting

Benefits of a custom ERP for the metalworking industry

Planning of production, work schedules and order fulfillment deadlines

Reducing costs and minimizing errors by automating business processes

Supply chain management, procurement, transportation and warehouse accounting

Optimization of resource utilization to support your sustainability strategy

Integration with other systems to control all aspects of metal production

Ensuring effective coordination between departments, divisions and locations

Functional ERP modules for metal production and processing

Depending on your business needs and budget, you can choose the necessary functional modules of the ERP system to automate business processes:

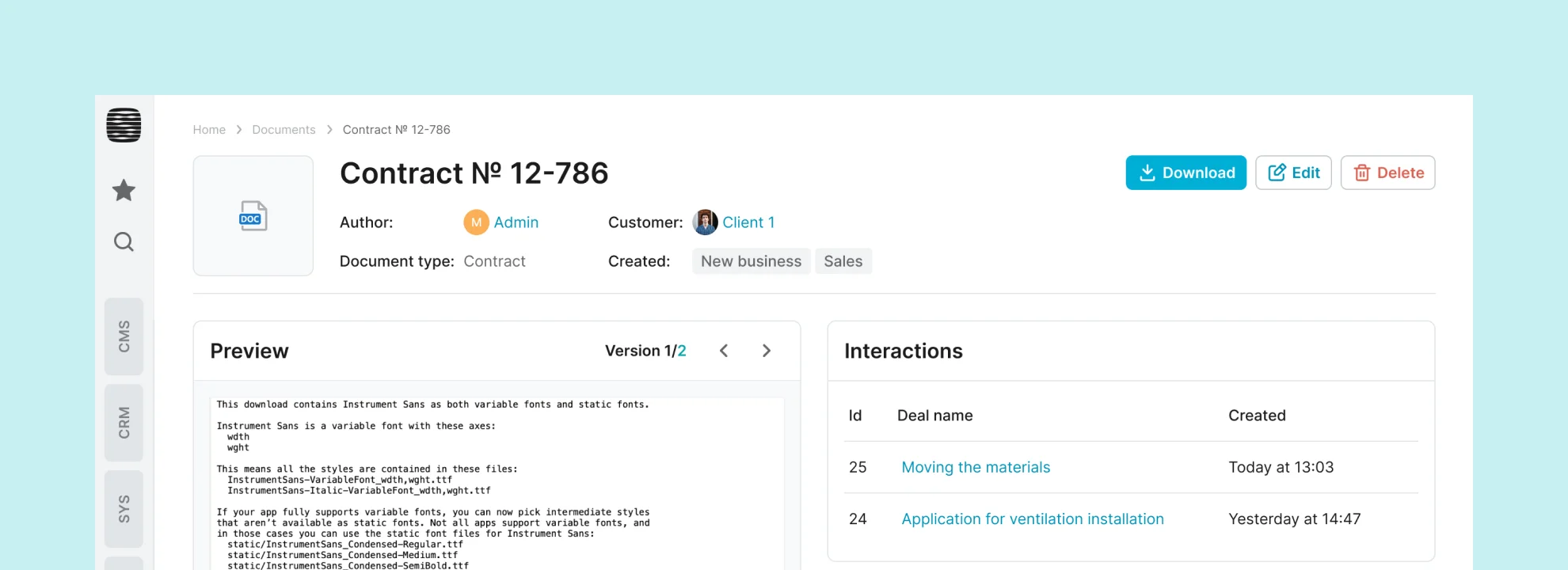

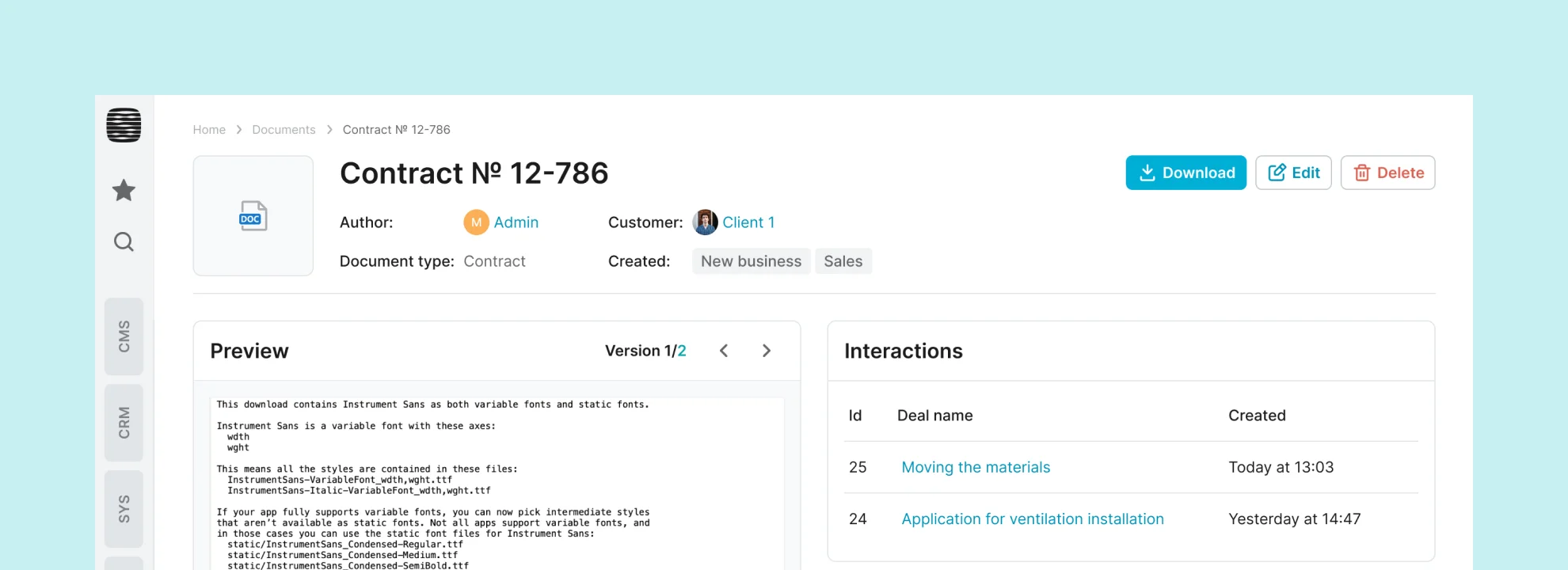

Order processing

Automate the entire order processing cycle: from creating and scheduling resources to invoicing and monitoring the status of execution

Manufacturing management

Ensure planning, scheduling, and control of production processes. Manage the product lifecycle and maintain high quality standards

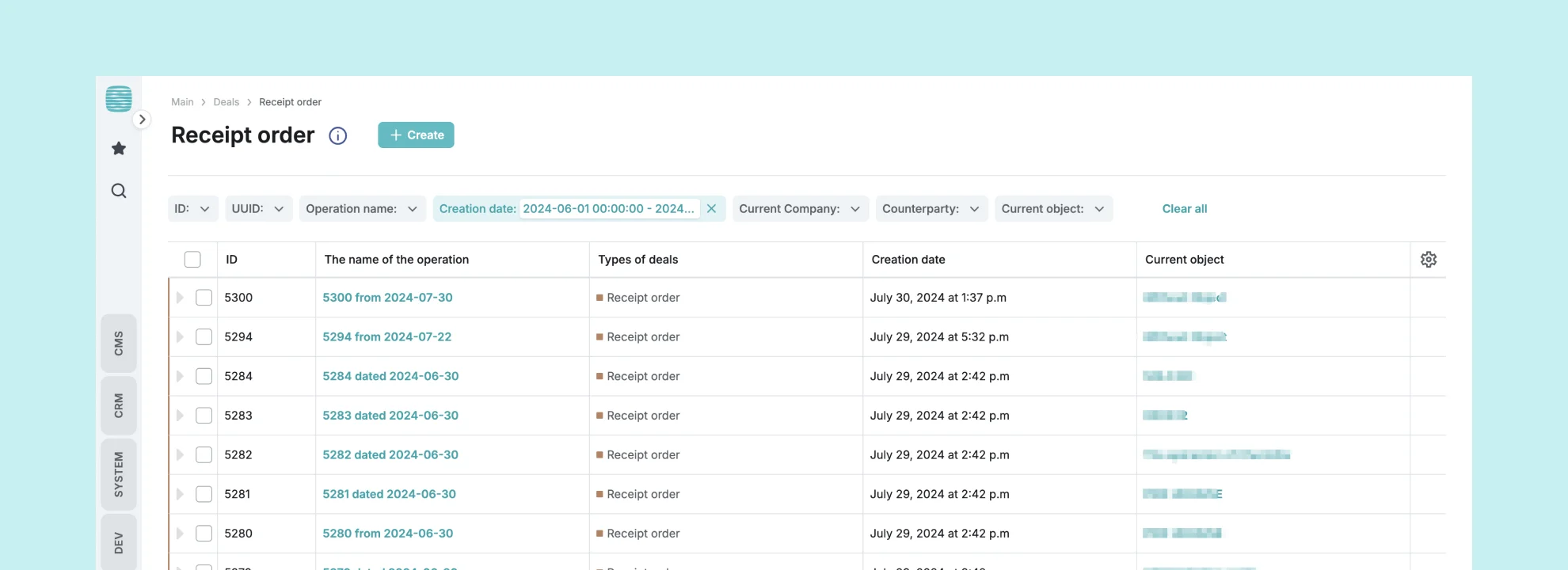

Procurement management

Optimize procurement processes, supplier management, and inventory monitoring. Ensure efficient sourcing of electronic components

Inventory management

Automate inventory management, plan and order products, control the movement of goods and materials in the warehouse, and quickly respond to changes in demand

Supply chain management

Optimize logistics processes and supplier management: ordering components and raw materials, maintaining warehouse records, controlling costs

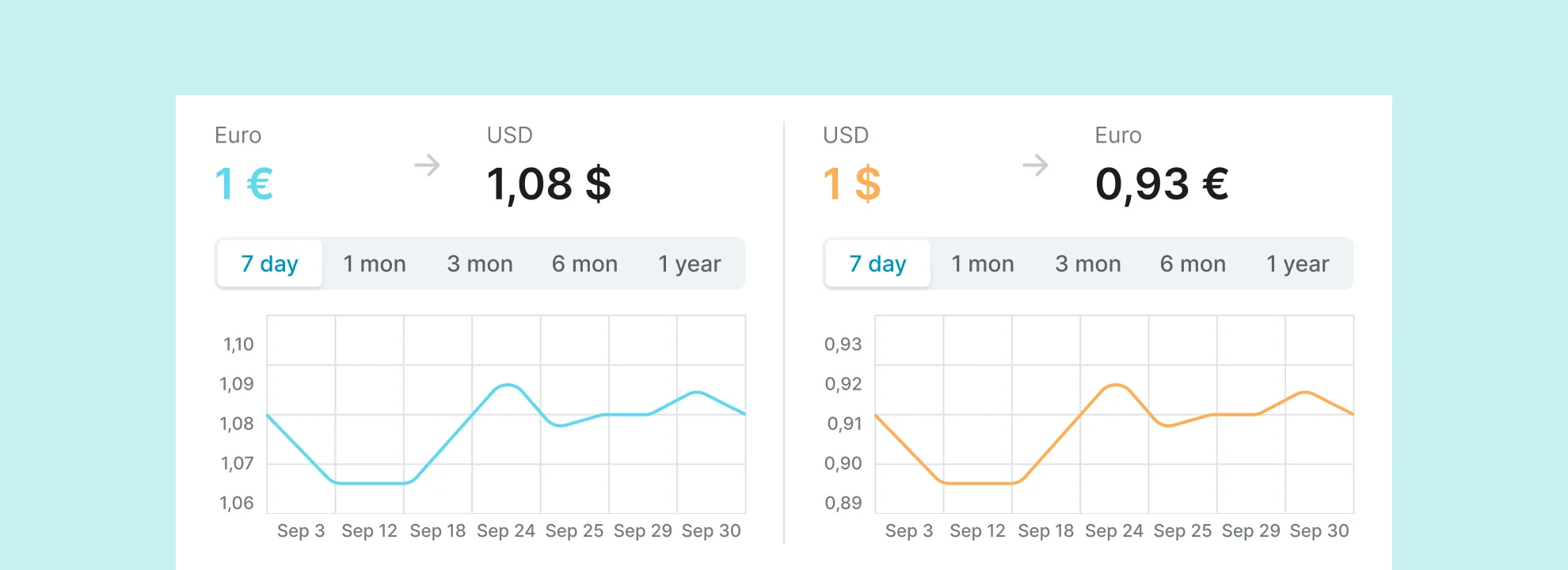

Financial management

Ensure comprehensive financial accounting: budget planning and administration, payment tracking, automation of calculations, analysis of indicators

Maintenance management

Plan maintenance and repair of equipment and machinery, effectively interact with service contractors, and monitor the condition of manufacturing assets

Human resources management

Plan work schedules, administer payroll, manage training and certification, and monitor compliance with safety and regulatory requirements

Order processing

Automate the entire order processing cycle: from creating and scheduling resources to invoicing and monitoring the status of execution

Manufacturing management

Procurement management

Inventory management

Supply chain management

Financial management

Maintenance management

Human resources management

Custom software development for manufacturing with FreshTech

Optimize production, supply chain, warehouse, and documentation management. Fast deployment based on the low-code platform Spiro: only the necessary functional modules for the efficient operation of your company

Energy industry Electronics and electrical engineering Light industry Metalworking industry Production of wood and paper Production of consumer goods Chemical industry Production of building materials Cosmetics and perfumery Engineering Production of furniture and fittings Pharmaceuticals and medicine Automobile industry Food industry

Frequently Asked Questions

What are the benefits of implementing a custom ERP system for the metalworking industry?

Is it possible to integrate ERP with other systems and applications?

What production management functions does an ERP system contain?

What are the benefits of deploying on Spiro low-code platform?

How do you implement an ERP system with Spiro?

What is the cost of ERP development for the metalworking industry?

We'll create

an ERP system for your business

Our manager will contact you.